Dealing with EOL, End of Life in Electronics

To the unfamiliar what we show in this picture may be what you think of when you visualize an electronic PCB Assembly. Just to give you a flavor of how much things have changed, this design is probably around 20 years old.

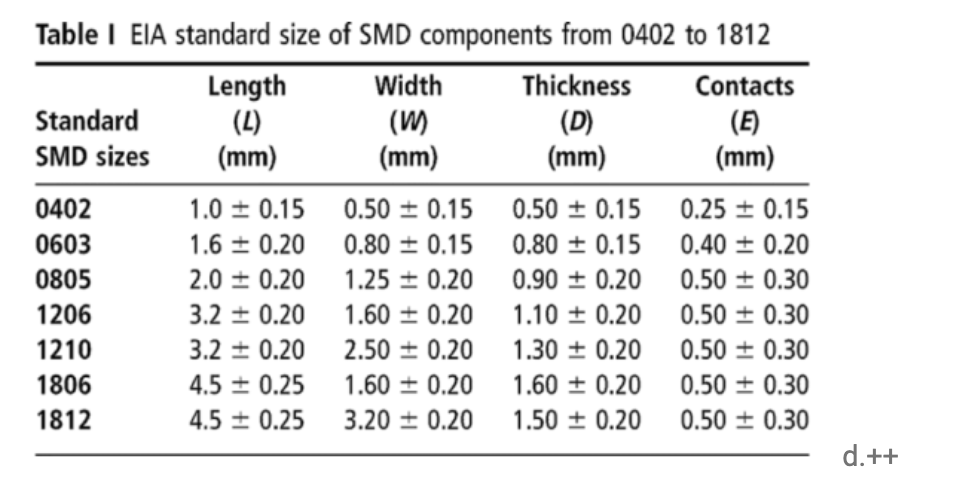

The blue components are capacitors and are now the size of about a spec of dust. In the chart below typically this capacitor would be a 0402 SMD size (see chart below), or about 1mm x 0.5 mm. There are new parts now that are half that size (0201). These parts are nearing the size of a spec of dust.

Also, these boards use ‘sockets.’ In the old days, there were plenty of reasons you might need this capability. The sockets then would accept a ‘through hole’ chip.

Surface Mount Technology

Today no one uses through hole chips or sockets. Everything today uses ‘Surface Mount’ technology where the chips don’t go through the board but are soldered right to the surface of the board. Oh and they’re tiny now as well and pack a ton of functionality in little packages.

So why did I go through this explanation?

- I want you to know what you are looking at when you review a PCB. If you are a business owner and have purchased some IP, and the electronics look like the one in the original picture, you are about to get a very rude awakening in the land of EOL (End of Life) components.

- Change is swift and furious in electronics and not preparing for the end of life will translate into supply issues, quality issues, delayed shipments and miserable customers. In fact, it may be so painful that you can’t ship at all.

So not being prepared and understanding what you are getting into, can be a minefield.++

Things to do to avoid an EOL catastrophe:

- Get EOL commitments from your component suppliers. You want to know how long they will be 1. supplied and 2. supported.

- Either hire a Components Engineer who lives and breaths this stuff, or, outsource your EOL issues to an independent design house.

- Use your design engineers to develop new products! Don’t bog them down with what most would consider not only annoying but a distraction which ‘to the company’ is not a distraction but an emergency! Also, engineers typically are not fans of this stuff. There is the occasional engineer who loves it, but they are by far the minority.

- Plan on it. Parts will go obsolete, and it will cost you time and money so make sure you add this to your life-cycle costs budget and get ahead of it!

Typically (not always!) companies will give you a heads up that their components are going obsolete. Hopefully, they give you enough of a window so that you can respond and begin taking action to find a new compatible substitute. By substitution, I don’t necessarily mean you will find a one-chip solution to replace your one chip that is going obsolete.

More likely you will need to design another smaller board that connects to the board where the part use to be (sometimes referred to as a daughter board or piggyback board).

- Start designing a new board thoroughly and proactively, so you don’t have to deal with this issue and pending emergency which will ensue. If you have a product with a very long life in the field, plan on it.

- Have a short term phase out plan while you are introducing your new design into the marketplace. Many customers need 24/7 uptime and are ‘just fine’ with using your old board (…with lots of OBS issues). Changing to a new board presents serious risks to your customer. What if the new board doesn’t work the same regardless of how hard you tried to mimic behavior? Most clients won’t want to be first adopters of your new design. So you need a plan to continue to support the old board while you introduce the new one.

We are here to help if you have any questions about the electronics you are reviewing. Feel free to Contact Us with your questions.